Table of Contents

Any product used in our daily life, such as a smartphone, laptop, or coffee, was transported in a shipping container at least once in its lifetime. Shipping containers are mainly reusable steel boxes used for the purpose of transporting goods by rail, road, and sea.

According to Statista, in 2017 about 2 (1.83) billion tons of products were transported in containers worldwide. About 90 percent of all the manufactured products in the world are shipped by sea. Of which, 60 percent are transported using steel containers, and the remaining oil and food grains are transported directly in the hull of ships.

Overview Of Shipping Container

Before the standardization of containers, products transported as cargo were packed in sacks, wooden barrels, or crates. As a result, a large number of dock workers were required for the manual loading-unloading of these products, although this task was quite risky. In addition, the products had to be packed in a tight space, which again took up to a few weeks. For each stoppage of the ship, the packages needed to be rearranged. As a result, unloading was very time-consuming and a hassle. For this inefficient process, loading and unloading would take much longer than the actual voyage itself.

According to the BBC, around the time of 1950, half a dozen serious accidents on average would take place in the Port of New York, and deaths every few weeks were also quite regular. For these reasons, the shipping industry has been trying to build a standard box for decades. But, there were disagreements between the trucking industry, the shipping industry, and the port regarding the size of the box. However, in the 1950s, as the number of dock workers’ accidents increased, so did the need to build a standard box.

Global Export Value Of Trade From 1960 to 2020 (in billion)

During this time, American trucking entrepreneur Malcolm Purcell McLean came forward to invent a shipping container. He wanted to design a box to make it easier and cheaper to transport goods by ship and truck. However, the U.S. regulations during that time restricted any trucking company to own a shipping line. That’s why In 1956, Malcolm bought two T2 tankers that were used in World War 2. He modified the two tankers in such a way that trailer-type containers could be carried both over and below the deck.

As a truck owner, he was trying to design an ideal-size container that could fit on a truck bed. After several attempts, his converted ship set sail with the containers. The design of his invented and patented container was strong and theft-resistant. Malcolm’s voyage from New Jersey to Houston in 1956 with 58 metal box trailer-type containers marked the beginning of a new era in global trading.

Several modifications were required to the container he designed and the ships began to be built around this newly designed container. Meanwhile, in 1966 the Moore-McCormick Company launched the first trans-Atlantic container service. The world’s first modern container ship was built by the Japanese and named Hakone Maru, which, in 1968, began to transport cargo.

This enormous ship was used to transport cargo on the Trans-Pacific route with 752 20-foot containers. By the 1980s, at least 90 percent of manufactured goods, such as designer clothing, food, home goods, electronics, or heavy machinery, were being shipped in containers to meet the demand of consumers worldwide.

According to the Wall Street Journal, in 2017 about 8 trillion dollars worth of products was being shipped using containers, which in 2019 increased to 8.4 trillion dollars. Whereas, in 2020, the combined GDP of the 27 countries of the European Union was just over 13 (13.31) trillion dollars. Several cargo and leasing companies around the world are mainly the owners of the majority of shipping containers. Leasing companies own more than 50 percent of the world’s total containers, and Triton International is one of the notable ones.

According to Forbes, the world’s largest cargo and container giant is Denmark’s APM Maersk with about 4.1 million containers and 713 ships, followed by the Swiss international cargo company Mediterranean Shipping Company or MSC with 39 million containers.

The Steel Box

A standard ISO shipping container for common use is 8 and a half (8.5) feet high, 8 feet wide, and 20 feet or 40 feet long. However, a container size of 20 feet is the most common. The main objective is to reduce shipping costs in container transportation and to facilitate easier container handling in cargo, truck, rail, crane, and port.

In 1956, the cost of loading per ton of loose cargo on a ship (without a container) was about 6 (5.86), while if using a standardized shipping container at the same time, the cost was 16 cents per ton for loading.

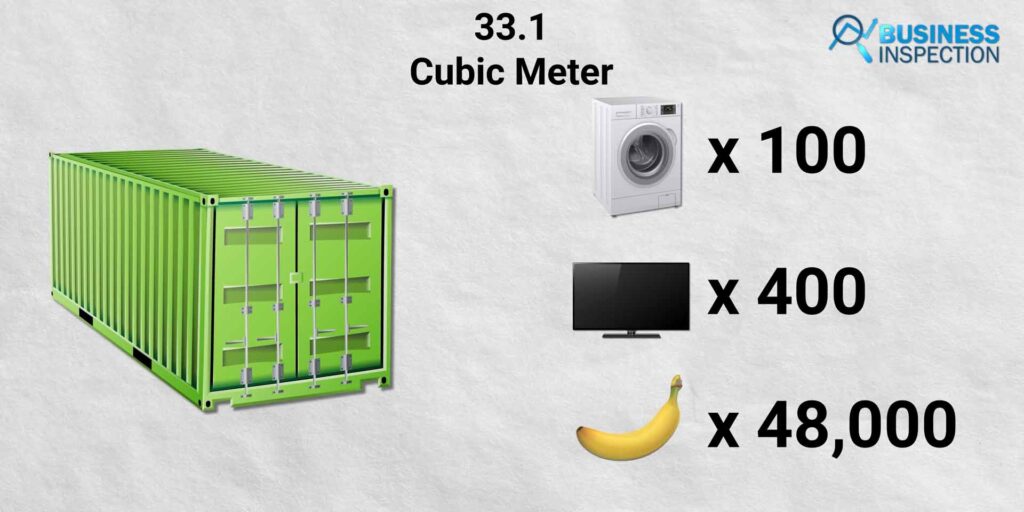

Also, some products may require a little more space than usual. For such items, there are high-cube containers, which can be up to 9 and a half feet (9.5) in height. The capacity of a standard 20-foot shipping container is more than 33 (33.1m³) cubic meters, which can store about 100 household washing machines, 400 flat-screen TVs, or 48,000 pieces of bananas. Other than that, small containers of 10 feet and 8 feet in length are also available. On the other hand, there are refrigerated containers for transporting some perishable products like food and flowers.

Impact On Global Trade

In the transportation of goods, Marshall McLuhan’s Global Village concept is now very practical. Anyone can buy products made on the other side of the world. The invention of the shipping container has revolutionized global trade.

Convenience

The convenience of loading containers is not limited to ships only, but also for trucks and freight trains. Due to the standard size of the container, it is suitable for transportation in cargo vessels as well as trucks, lorries, and freight trains. Containers can be easily transported from ship to port, then on to truck-beds and freight trains without repacking for road or rail transport.

In this way, without any direct handling of the products, they reach from the producer to the consumers, retailers, vendors, or distributors. These shipping containers, made of very strong and robust metal, remain protected in the extreme weather of the sea. Because of these advantages, according to Our World in Data, global trade has grown at least 57 times in the last 100 years from 1910 to 2010, which can be largely attributed to the invention of the shipping container.

Efficiency

Product shipment using containers can be done very fast and in an organized process. Global trading has become much easier and cheaper as a result of increasing efficiency in each stage of transit with the help of strategic cargo-placement planning and the use of the software. For example, a ship can easily and in a short time make a trip from Hong Kong to Jeddah via Colombo and finally to New York. In this case, the containers bound for New York will be placed at the bottom, then above them the containers bound for Jeddah, and the Colombo-bound containers will be placed at the very top.

This reduces the need for reshuffling while unloading containers which makes unloading an easier process. This saves a lot of time in terms of shipping. According to Estimating the Effects of the Container Revolution on World Trade published in the Journal of International Economics in 2016, the productivity of dock laborers before containerization was less than 2 (1.7) tons per hour, which increased to 30 tons per hour after containers started being used. (image -3).

Cost Effective

Containers have reduced the cost of cargo transportation by at least 90 percent. Moreover, the use of containers has reduced the cost of product loading by more than 97 percent. According to the BBC, the cost of transporting a ton of goods on a ship in 1954 was 420 USD (without using containers), while in 2016 the same amount of goods could be transported for 50 dollars and less using containers. In 2021, loading and unloading one kg of banana as loose cargo will cost around BDT 10, whereas with containers, the entire shipping process (including loading, unloading, and the voyage) will cost only BDT 7.

Product shipments from one side of the world to the other have become very cost-effective due to the uniform size and design, cost management, product packaging, and ease of loading-unloading of shipping containers. In addition, the cost of manufacturing containers is low as they are made using corrosion-resistant corten steel and maritime paint, in a certain size and in bulk amounts. Furthermore, as they are used mainly through leasing, they are even less costly to use. This has a direct positive impact on global trade.

Ease Of Process & Tracking

Before the invention of the container, the production of a product to deliver to the consumer involved a lot of labor. Initially, the packaging was done by workers at the production facility. It was then loaded on truck rail and unloaded to the port again, from there it was re-loaded by workers on the ships and unloaded at the destination port. Similarly, workers were needed in every step until it reached the consumer. Since the invention of the container, the need for manual labor in product loading and unloading has been greatly reduced.

Container tracking has also become much easier than before. The BBC Box Project comes into the discussion whenever container tracking is mentioned, which gave an idea of the journey a container takes through roads, rail, and on the seas of the world.

Dockers Safety

Containerization has greatly reduced shipping-related accidents worldwide. Because most of the work is now being done using machines, the workforce as well as the number of accidents has gone down significantly. According to a US study, in the 1950s, before the use of containers, every year half of the dockers (longshoremen) who worked at the dock suffered from accidents, where one out of every 6 people would suffer a disabling injury. According to the US National Research Council, there were more than 7,000 accidents on the US Pacific Coast in 1954 alone. Containerization has greatly reduced the number of these accidents.

Ease Of Storage

Then there is the matter of storage cost. While shipping products, storage is an important requirement at different destinations, for which an office or storehouse is required. But the standardized steel box containers can be easily stored in the port area. In addition, loose cargo suffered heavy losses during shipping due to theft, robbery, and natural disasters. The safety of the products has increased through containerization.

Global Production

Container use has reduced the hassle of global shipping as well as making shipping more efficient and tracking easier, increasing global shipping and consequently helping to achieve global production. As shipping has become easier and more efficient, manufacturing companies are able to use the cheaper workforce of developing countries. A great example is the garment (RMG) industry of Bangladesh, whose products are being sold worldwide by famous global brands.

Another big example is China, which is the biggest beneficiary of this invention. The country makes most of the world’s electronics products, including tech gadgets like the iPhone. According to Statista, before the standardization of containers in 1950, the global export value was 62 billion. But in 2019, global exports were more than 19 trillion dollars before the Covid-19 pandemic.

There is currently a downtime in the global shipping industry due to the Covid-19 pandemic. Issues like the global economy and globalization are deeply connected with the story of the shipping container, so it is pretty predictable that the growth of this industry and the growth of global trade will continue hand in hand.

Leave a Comment